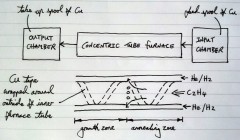

My sketch of the roll-to-roll set-up proposed by the Mechanosynthesis group now based at MIT for high-throughput production of graphene.

A packed session on large-area graphene synthesis re-enforced the fact that there’s growing interest in making the material in amounts that push beyond lab-scale studies. On TMR+ this year, we’ve already featured a trio of commercial operations: Haydale in the UK, Graphene Nanochem, which has its production site in Malaysia, and – from the US – the University of Pennsylvania spin-out, Graphene Frontiers.

Graphene Frontiers has won a number of fans thanks to its roll-to-roll approach (see: roll-to-roll production could ramp up market opportunities for graphene), but they’re not the only ones exploring the concept.

A new twist on roll-to-roll production

Eric Polsen talked the audience through a concentric tube furnace design, which features an interesting twist on the roll-to-roll idea. Polsen is a member of the Mechanosynthesis group led by John Hart, who was previously at the University of Michigan and is now based at MIT.

As Polsen commented, roll-to-roll opens to the door to high-throughput production and has proven successful in delivering numerous materials, such as carbon fibre, in large quantities. He also acknowledged that they weren’t the first to look at how roll-to-roll techniques could be applied to graphene, citing studies by Hesjedal (2011) and Kobayashi (2013).

What does make the Mechanosynthesis team’s approach special though is the path that the copper foil (the substrate for CVD growth of graphene) takes from the feed spool through the tube furnance and into the collection chamber. The design features concentric tubes in which a carbon source (ethylene) is passed through the centre and the reducing agents (He/H2 are routed around the annulus. Wrapped around the inner tube is the copper tape, which can then travel through two distinct zones – first, an annealing zone, and then the growth zone, which is created as the carbon source enters through holes halfway along the inner tube.

Polsen explains that the tubular approach gives them much better control over vacuum conditions. The next step for the team is to ramp up the throughput via optimization of the synthesis recipe to acheive full coverage at speeds greater than 1 m/min.

Further reading on TMR+

MRS Fall 2013 highlights – part five (final)

MRS Fall 2013 highlights – part four

MRS Fall 2013 highlights – part three

MRS Fall 2013 highlights – part one

Pingback: MRS Fall 2013 highlights – part one | TMR+

Pingback: MRS Fall 2013 highlights – part five (final) | TMR+

Pingback: MRS Fall 2013 highlights – part four | TMR+