Lab-on-a-chip (LOC) technology provides an ultra-compact solution for environmental monitoring and point-of-care diagnostics, to name just a couple of key applications. Measurement systems can be portable, easy-to-use, and require only small quantities of sample and reagents, but despite these strong selling points LOC devices have yet to realize their full potential in terms of market success.

“One of the main reasons LOCs don’t make it to market is that the methods used to fabricate them are often not transferable to industrial-scale production,” commented Christoph Baum, group manager at the Fraunhofer Institute for Production Technology (IPT) in Aachen, Germany.

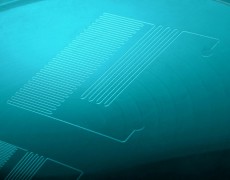

To tackle the problem, IPT has teamed up with 11 European partners to streamline LOC production. Their plan is to develop a common manufacturing platform that combines roll-to-roll and inkjet printing, and integrates the key components of a LOC – microfluidic channels for liquid transport, optical components for analysis, and electrical circuits for channel heating and readout – on a layer-by-layer basis.

Series production

Rather than use injection molding or wet chemical etching to produce microfluidic channels, the group’s approach instead involves transferring the negative imprint of the channel layout onto a roller to create an embossing cylinder that then imprints a pattern of depressions on a continuous roll of film. In a subsequent step, electrical circuits can be printed on the film using an inkjet printer fed with conductive ink.

The four year project, dubbed ML2, is due to deliver in Q3 2016 and is funded (Euro 7.69 million) under the European Commission’s seventh framework programme in the area of smart components and smart systems integration.

Value proposition

The goal is to make LOC-based devices more price-competitive in markets such as pregnancy testing or HIV screening, allowing developers to bring high-sensitivity and high-reliability designs to these areas.

The team aims to have demonstrator platforms built and individual manufacturing processes optimized by 2014. Once this is achieved, the next steps will be to piece the manufacturing process together and implement the entire sequence on an industrial scale.